The world of firearms is rich with diversity and fascinating historical developments. Among the various types of guns, there is a particular charm to muzzleloaders – weapons that ignite their propellant charge from the muzzle end of the barrel. This article delves into the captivating realm of the muzzleloader.

Definition of a Muzzleloader

A muzzleloader can be defined as a firearm that requires manual ammunition loading through the muzzle or open end of its barrel rather than using a breech-loading mechanism. Unlike modern firearms, where bullets are loaded from the rear or side, muzzleloaders are loaded directly into the front end or “muzzle” of the barrel. Depending on their intended use, muzzleloaders typically have a smoothbore or rifled barrel.

Smoothbore barrels lack spiral grooves on their inner surface and are primarily used for shooting round balls or shot cartridges. Rifled barrels feature helical grooves that impart spin to projectiles for enhanced accuracy when shooting conical bullets or projectiles.

Historical Significance and Evolution of the Muzzleloader

Muzzleloaders hold an exceptional place in history as they shaped warfare and hunting practices for centuries. The origins of muzzleloading firearms can be traced back to ancient China during the Tang Dynasty (618-907 AD), where early prototypes known as “fire lances” were developed.

These fire lances consisted of bamboo tubes packed with gunpowder and shrapnel-like projectiles ignited by flames at one end. In Europe, the first true handheld muzzleloading firearms came into prominence around the 15th century during the Renaissance period.

These early matchlock muskets featured a slow ignition system whereby an external burning cord or “match” was lit and held in a moveable serpentine lever mechanism, which, when triggered, brought the lit match into contact with the powder charge in the barrel. The evolution of muzzleloaders continued as technological advancements led to the introduction of more efficient ignition systems.

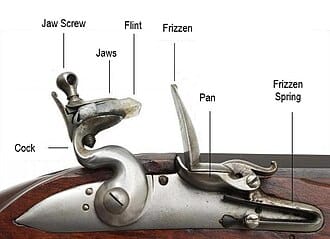

Flintlock mechanisms emerged in the 17th century and utilized a striking flint against a steel frizzen to generate sparks that ignited the priming powder within a pan, igniting the main propellant charge. This innovation enhanced reliability and ease of use compared to matchlocks.

By the 19th century, percussion cap ignition revolutionized muzzleloaders. This system employed a small copper or brass cap containing a fulminate compound placed on a nipple at the rear of the barrel.

When struck by a hammer or striker mechanism, it created an instantaneous spark that ignited the main propellant charge. Percussion caps offered faster ignition times and increased resistance to weather conditions, making muzzleloaders more reliable.

Modern inline muzzleloaders have improved performance today through advancements such as enclosed ignition systems and advanced rifling techniques. These innovations have enabled hunters and shooting enthusiasts to experience historical nostalgia and remarkable accuracy with their muzzleloading firearms.

Muzzleloader Types

In the realm of firearms, muzzleloaders have held a significant place in history and continue to captivate enthusiasts today. While various types of muzzleloaders are available, three primary categories dominate the market: flintlock muzzleloaders, percussion cap muzzleloaders, and inline muzzleloaders. Each type has its own distinctive characteristics and historical significance.

The Flintlock Muzzleloader

The flintlock muzzleloader is a classic and iconic firearm that played a crucial role in shaping the world as we know it today. The flintlock mechanism strikes a piece of flint against steel to create sparks that ignite gunpowder in the flash pan. This ignition then travels through a small hole called the touchhole into the main powder charge behind the projectile, propelling it forward.

Flintlocks possess an inherent charm that stems from their historical significance but presents some unique advantages and disadvantages. One advantage is their simplicity; with relatively few parts, they are easier to understand and maintain than more complex modern firearms.

Additionally, flintlocks offer a remarkable connection to history when handling them. However, despite their allure, flintlocks do have some drawbacks.

They require careful preparation before each shot, including priming the flash pan with powder and ensuring proper positioning of the frizzen (the metal plate that holds both the flint and flash pan).

Furthermore, extreme weather conditions such as rain or high humidity can significantly impact their reliability since moisture can affect ignition efficiency.

The Percussion Cap Muzzleloader

The introduction of percussion caps revolutionized firearms technology by providing more reliable ignition than traditional flintlocks. Percussion cap muzzleloaders utilize small copper or brass caps filled with a sensitive explosive compound placed on a hollow nipple.

When the hammer strikes the cap, it creates a spark, which travels through the nipple and directly ignites the main powder charge.

The percussion cap ignition system brought numerous benefits to muzzleloaders. It eliminated many of the challenges posed by flintlocks, such as susceptibility to weather conditions and reliability issues.

Furthermore, percussion caps allowed for faster and more consistent ignition, improving accuracy and overall performance. With percussion cap muzzleloaders, shooters enjoy heightened confidence due to their simplicity and increased reliability.

These firearms still evoke a sense of nostalgia while offering improved efficiency over flintlocks. However, it is worth noting that obtaining or manufacturing percussion caps may be more challenging than other types of ammunition in some regions or during limited availability.

The Inline Muzzleloader

Inline muzzleloaders represent an evolution in design that addresses some limitations of traditional muzzleloaders like flintlocks and percussion caps. Inline designs position the primer directly behind the powder charge in line with the barrel, enhancing ignition efficiency and reducing delays between firing mechanisms.

The development and subsequent popularity of inline muzzleloaders have revolutionized the world of black powder firearms by introducing features not found in their predecessors.

Inline designs often incorporate modern materials like synthetic stocks or stainless steel barrels for increased durability and resistance to harsh weather conditions. Inline muzzleloaders offer several key advantages over traditional designs.

They typically feature faster lock times (the delay between trigger pull and ignition), improved accuracy due to consistent ignition pathways, reduced recoil thanks to advanced stock designs, and enhanced ease of use with simplified primer installation systems.

Additionally, inline rifles can utilize various sighting options, such as scopes or fiber optic sights, for increased precision at longer ranges.

Components and Accessories of a Muzzleloader

The barrel of a muzzleloader is a vital component that greatly influences its performance. Muzzleloaders come in various barrel types, with some popular options being octagonal and round barrels. Octagonal barrels were favored in the past for their increased rigidity, which enhanced accuracy.

Round barrels are more commonly used today due to their ease of manufacturing and aesthetic appeal. Additionally, stainless steel has gained popularity as the material of choice for modern muzzleloader barrels due to its durability and resistance to corrosion.

Stock options (wood, synthetic)

The stock of a muzzleloader provides stability and contributes to the overall aesthetics of the firearm. Traditionalists often prefer wooden stocks for their classic appearance and natural feel. Wood stocks can be made from various woods, such as walnut or maple, each offering distinct grain patterns and levels of durability.

On the other hand, synthetic stocks have gained popularity for their durability and weather resistance. Made from materials like fiberglass-reinforced nylon or composite blends, synthetic stocks offer excellent longevity while being less susceptible to warping or damage caused by exposure to moisture.

Sights (open sights, fiber optic sights)

Accurate aiming is crucial in any firearm, including muzzleloaders. Sights play a vital role in achieving precise target acquisition. Muzzleloaders typically feature open sights or fiber optic sights.

Open sights consist of front and rear iron sights requiring accurate shooting alignment. These traditional mechanical sights are durable but may pose challenges under low light conditions or when targeting small objects at longer distances.

In contrast, fiber optic sights utilize small strands of optical fibers that gather ambient light to create bright dot-like aiming points on both the front and rear sights. This allows for improved visibility and quicker target acquisition, even in dim lighting conditions.

Ramrods and cleaning rods (materials, length, purpose)

Ramrods and cleaning rods are essential tools for every muzzleloader shooter. A ramrod is a long rod typically made of wood or synthetic materials used to load the projectile into the barrel by pushing it down firmly on top of the powder charge.

Ramrods often feature a threaded end for attaching accessories, such as bullet pullers or cleaning attachments. On the other hand, cleaning rods are primarily used to clean residue from fouling after shooting sessions.

They come in different lengths depending on the barrel length of the muzzleloader being cleaned. Generally made from materials like steel or aluminum, cleaning rods have specialized tips or brushes designed to scrub away residue while protecting the barrel’s rifling effectively.

Powder measures and flasks (types, capacity)

Accurate powder measurement is vital for consistent performance when loading muzzleloaders. Powder measures and flasks are designed explicitly for this purpose.

Powder measures come in various types, such as volumetric or adjustable systems that allow precise control over powder charges. These devices ensure consistent volume measurements for reliable shooting results.

Flasks are portable containers for storing black powder charges safely during extended shooting sessions or hunts. They come in different sizes with varying capacities to accommodate individual shooter needs and preferences.

Ammunition for Muzzleloaders

Black powder vs. Smokeless powder

Regarding propelling projectiles in muzzleloaders, there are two primary choices: black powder and smokeless powder. Black powder is a traditional form of gunpowder composed of sulfur, charcoal, and potassium nitrate (saltpeter). Known for its distinctive smell and dense white smoke upon firing, black powder imparts a classic feel to the muzzleloading experience.

In contrast, smokeless powder is a more modern fuel comprised of nitrocellulose-based compounds. It offers cleaner burning characteristics and generates less smoke compared to black powder.

Differences between black powder and smokeless powder

Black powder differs from smokeless powder in terms of properties and performance characteristics. Black powder is less stable than smokeless powder, requiring careful storage to prevent accidental ignition.

Additionally, black powder combustion produces more fouling residue, necessitating frequent cleaning to maintain consistent accuracy. Smokeless powders are more stable but require specific load data for safe usage due to their varied burn rates.

Advantages/Disadvantages for each type

The choice between black powder and smokeless powder depends on personal preferences, shooting goals, and legal restrictions in some cases. Black powder enthusiasts appreciate the historical authenticity it provides alongside the unique experience of shooting muzzleloaders.

However, the need for meticulous cleaning and its limited range compared to smokeless alternatives can be considered disadvantages for some shooters. Smokeless powders offer a cleaner shooting experience with less residue buildup, allowing for higher velocities and longer effective ranges. Still, they may lack the nostalgic charm associated with traditional black powder.D

Bullets for Muzzleloaders

Different bullet types (round balls, conical bullets)

Muzzleloaders utilize various bullet types depending on the shooter’s intended use or preference. Round balls are spherical lead projectiles commonly used during early muzzleloading times due to their ease of manufacturing. They provide decent accuracy at shorter distances but typically lack aerodynamic stability beyond certain ranges.

Conical bullets, on the other hand, feature a cylindrical shape with a pointed tip that offers improved ballistic efficiency over round balls at extended distances. They have become increasingly popular among modern muzzleloader enthusiasts seeking enhanced accuracy and terminal performance.

Bullet materials (lead, copper-plated)

Muzzleloader bullets are predominantly made from lead due to their softness and malleability, allowing them to engage the rifling effectively. Lead bullets offer excellent expansion upon impact, ensuring optimal energy transfer for humane kills during hunting applications.

However, copper-plated or jacketed lead bullets have gained traction in recent years. Copper plating enhances bullet durability and reduces fouling compared to bare lead projectiles while maintaining desirable terminal ballistics.

Sabots vs. Patched Round Balls

Sabots and patched round balls represent two distinct approaches to projectile design in muzzleloaders. Sabots are plastic or polymer sleeves that hold smaller caliber bullets or projectiles within a larger diameter sabot itself. This increases velocities, improved aerodynamics, and better long-range performance due to reduced wind resistance.

Patched round balls involve wrapping a cloth patch around a spherical projectile before loading it into the muzzleloader barrel. The patch acts as a gas seal between the bullet and the barrel’s rifling, enhancing accuracy by consistently engaging with the rifling grooves.

Explanation of sabots and their purpose

Sabots enable shooters to use smaller caliber projectiles while taking advantage of their muzzleloader’s larger bore diameter. By reducing air drag through their sleek profile, saboted bullets achieve flatter trajectories, higher velocities, and improved long-range accuracy compared to traditional projectiles.

Traditional patched round balls – advantages/disadvantages

Patched round balls have been used for centuries in muzzleloaders due to their simplicity and historical significance. They offer good accuracy at shorter ranges but tend to lose stability beyond certain distances due to their spherical shape lacking aerodynamic features like boat tails found on modern ammunition.

Additionally, patched round balls can be more challenging to load than bullets, requiring careful attention to ensure proper patching and seating. Still, they retain the classic charm that appeals to traditional muzzleloader enthusiasts.

Conclusion

The components and accessories of a muzzleloader play a significant role in its overall performance and user experience. Each element contributes to accuracy, durability, and functionality, from the barrel type and material used to the stock options, sights, and tools like ramrods and cleaning rods.

Similarly, ammunition choices such as black powder or smokeless powder alongside different bullet types and materials impact trajectory, range, and terminal ballistics.

Whether one prefers modern innovations like sabots or embraces the traditional elegance of patched round balls, muzzleloaders offer a unique shooting experience that connects us with historical roots and contemporary advancements in firearm technology.

So, seize the opportunity to delve into this fascinating shooting sports realm where tradition meets innovation for an unforgettable journey into marksmanship mastery.